verious process of concentration of ore

BYJU'S

Concentration of Ore Definition, Types and Properties of Ore

WebConcentration of Ore Understand the properties of Ore and its types, Hydraulic Washing, Magnetic Separation, Froth Flotation Method, Leaching and more

Definition, Methods of Separation, Examples GeeksforGeeks

WebOre concentration can be accomplished through a variety of methods, including hydraulic washing, magnetic separation, froth flotation, and leaching The next sections go through

Concentration Of Ore: Types, Procedures, Extraction

WebGiven below are 4 methods of concentration of ore: 1 Hydraulic Washing Hydraulic washing is used for the concentration of ores in which there is a noticeable difference in

Concentration of Ore Biology Reader

Web1 Comment / Chemistry / By Supriya N The concentration of ore is a method of eliminating gangue particles or other impurities Oredressing and benefaction are the alternative

123: Ore Genesis Geosciences LibreTexts

WebThe various theories of ore genesis explain how the various types of mineral deposits form within the Earth’s crust Ore genesis theories are dependent on the mineral or

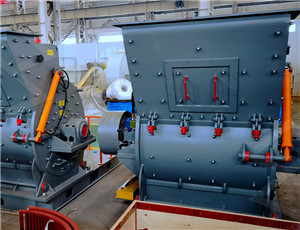

Mineral processing Metallurgy, Crushing Grinding

Webmineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue It is the first process that most ores

Methods of concentration of Ores – Gravity Separation

WebThe different methods used for the concentration of ores are the froth floatation method, gravity separation, leaching method and electromagnetic separation Methods of

Reading: Ore Genesis Geology Lumen Learning

WebOre genesis theories are dependent on the mineral or commodity Ore genesis theories generally involve three components: source, transport or conduit, and trap This also

(PDF) Overview of Mineral Processing Methods ResearchGate

WebIt is a process of ore preparation, milling, and ore dressing or ore beneficiation In this context, the effect of different process variables such as particle size (60 + 100 mesh;

Concentration of ore SimplyScience

WebConcentration of ore is a step involved in the process of extraction of metal from its ore Unwanted rocks and grit are eliminated from mineral ore in this process Hydraulic

Concentration of Ore Biology Reader

WebThe ore concentration is defined as the chemical process of eliminating impurities like sand, rocks, silt, grit etc from the ore to extract the metals In simple words, the concentration of ore is the method of separating ore

Extraction of Metals Methods of Extraction of

WebThe extraction of metals and their isolation occurs over a few major steps: Concentration of Ore – Here the ore is separated from earthy impurities Isolation of metal from concentrated Ore – Here the ore is converted to

Definition, Methods of Separation, Examples

WebNov 28, 2021 We achieve a concentrated ore with a high percentage of metal by eliminating these impurities The concentration of ore, also known as ore enrichment, is the process of removing gangue particles from ore in order to enhance the percentage of metal in the ore The difference in physical or chemical properties of the ore and the

232: Principles of Extractive Metallurgy Chemistry

WebJul 12, 2023 Extractive metallurgy is a branch of metallurgical engineering wherein process and methods of extraction of metals from their natural mineral deposits are studied The field is a materials science, covering all aspects of the types of ore, washing, concentration, separation, chemical processes and extraction of pure metal and their

verious process of concentration of oreExtracting

WebThe grade or concentration of an ore mineral or metal as well as its form of occurrence It takes multiple steps to extract the important element from the ore 13 Nov this video tell you the various techniques used to concentration of ore this video will also describe the process of it 立即联系/Live Chat

Methods of concentration of Ores – Gravity Separation

WebAlso known as enrichment, the concentration of ores is the method of removing impurities and other unwanted particles from the ore The removal method of the gangue particles or the unwanted particles depends on the difference in physical or chemical properties of the ore and the impurities The minerals present in ores are found in the form of

What is meant by Concentration of Ores? GeeksforGeeks

WebFeb 7, 2022 The procedure of ore concentration is a critical stage in obtaining pure metal from ore Separating ore from gangue particles is required for metal extraction Ore discovered in the soil contains several impurities such as sand, grit, pebbles, and so on, which are collectively referred to as “Gangue” The initial step in metal extraction

The processes of formation of mineral deposits are grouped into

WebAs we know, an ore is composed of ore minerals and gangue, which can be utilised for a profitable extraction of one or mere metallic compounds or metals The entire crust of the earth consists of minerals They occur as solid masses, or rocks of which the earth's crust is composed, or as local accumulator s of varying size, such as veins, pockets or

Iron processing Ores, Smelting, Refining Britannica

WebConcentration refers to the methods of producing ore fractions richer in iron and lower in silica than the original material Most processes rely on density differences to separate light minerals from heavier ones, so the ore is crushed and ground to release the ore minerals from the gangue Magnetic techniques also are used

processes in concentration of ores krystynazrzeszowa

Webverious process of concentration of ore methods of concentration of different ores methods of concentration of different ores 14 Jun 2012 Gulin supply Mining and USA Process for the concentration of

Concentration of ore SimplyScience

WebConcentration of ore is a step involved in the process of extraction of metal from its ore Unwanted rocks and grit are eliminated from mineral ore in this process Hydraulic washing, froth floatation process, magnetic separation and chemical separation are some of the techniques used for concentrating or purification of ores Hydraulic washing:

Concentration of Ore Learn Important Terms and

WebOct 12, 2023 The concentration of ore is the removal of impurities from metal ore In iron ore, the nonmagnetic impurities from magnetic iron ore are separated by the magnetic separation process Leaching is a process which involves the use of chemical substances to dissolve metal ore which has significant use in the concentration process as it is

processes in concentration of ores krystynazrzeszowa

Webverious process of concentration of ore methods of concentration of different ores methods of concentration of different ores 14 Jun 2012 Gulin supply Mining and USA Process for the concentration of

Concentration of ore SimplyScience

WebConcentration of ore is a step involved in the process of extraction of metal from its ore Unwanted rocks and grit are eliminated from mineral ore in this process Hydraulic washing, froth floatation process, magnetic separation and chemical separation are some of the techniques used for concentrating or purification of ores Hydraulic washing:

Concentration of Ore Learn Important Terms and

WebOct 12, 2023 The concentration of ore is the removal of impurities from metal ore In iron ore, the nonmagnetic impurities from magnetic iron ore are separated by the magnetic separation process Leaching is a process which involves the use of chemical substances to dissolve metal ore which has significant use in the concentration process as it is

Common Basic Formulas for Mineral Processing

WebMar 20, 2016 The treatment of such an ore by flotation or some other process of concentration has this purpose: to concentrate the copper into as small a bulk as possible without losing too much of the copper in doing so The value of crude ore by perfect concentration is then $1146 for the lead concentrate and $1118 for the zinc, or a total

(PDF) Iron ore pelletization ResearchGate

WebDec 31, 2015 Arrium Australia 0810 0810 0440 440 Iron Ore The pelletizing process involves the preparation of ra w materials; the proportioning and mixing of raw materials; the formation, preheating, and

Lead processing Mining, Concentrating, Refining Britannica

WebLead processing Mining, Concentrating, Refining: Once the ore is removed from veins (narrow channels) or lodes (roughly spherical deposits) in the Earth, usually at depths of about 60 metres, the ore is treated at concentrating mills Here the ore is finely crushed, sometimes to particle diameters of less than 01 millimetre (0004 inch), and then treated

Ores And Minerals Definition, Types Differences with

WebOre is the rock from which the metal is extracted in a convenient and economical way Ore has a composition that is definite Metals that occur naturally in the earth’s crust are called minerals Minerals that can profitably be used to get the metal are called ores Q2

CBSE Class 12 : Concentration of Ores, Chemistry

WebOres are solid materials that can be used to produce pure metals Concentration, dressing, or benefaction of ores is extracting undesirable particles from ore There are various steps to it The variations in physical characteristics of the existing metal complex and that of the gangue are used to separate the needed material from the ore

Ore Definition, Types Examples Video Lesson

WebJan 10, 2022 What is Ore? An ore is a naturally occurring deposit of geologic material (rock) that includes a sufficient quantity of one or more valuable elements or compounds that it can be extracted for

What Is Mineral Processing in Mining? Flyability

Web3 Concentration Concentration is the process of breaking down the materials until the desired concentration of crude material is reached There are several different techniques for accomplishing the target concentration including: Automated ore sorting Automated ore sorting uses optical sensors to sort the rock into categories

Concentration of Ores GeeksforGeeks

WebNov 26, 2022 Concentration ore refers to the process of removing matrix or gauge from an ore Occurrence of Metals Some elements, such as carbon, sulphur, gold, and noble gases, are found in their free state in the earth’s crust, while others are found in mixed forms The amount of elements varies The most plentiful metal on the planet is aluminium

Concentration Of Ore: Types, Procedures, Extraction

WebAug 29, 2023 Concentration of ore can be explained as a method by which gangue is separated from the ore of the metalThe process is also known as dressing or benefactionGangue is the combined name of the impurities like sand, clay, grit, etc Gangue needs to be separated because minerals are present in high concentration in

What Is Mineral Processing in Mining? Flyability

Web3 Concentration Concentration is the process of breaking down the materials until the desired concentration of crude material is reached There are several different techniques for accomplishing the target

Concentration of Ores GeeksforGeeks

WebNov 26, 2022 Concentration ore refers to the process of removing matrix or gauge from an ore Occurrence of Metals Some elements, such as carbon, sulphur, gold, and noble gases, are found in their free state in the earth’s crust, while others are found in mixed forms The amount of elements varies The most plentiful metal on the planet is aluminium

Concentration Of Ore: Types, Procedures, Extraction

WebAug 29, 2023 Concentration of ore can be explained as a method by which gangue is separated from the ore of the metalThe process is also known as dressing or benefactionGangue is the combined name of the impurities like sand, clay, grit, etc Gangue needs to be separated because minerals are present in high concentration in

What is concentration of ore? BYJU'S

WebConcentration Definition: The process of removal of the gangue from the Ore is known as Concentration or Dressing or Benefaction There are numerous methods of concentration and the methods are chosen based on the properties of the ore Suggest Corrections 3

Current Status of CopperOre Processing: A Review

WebSep 8, 2021 In recent times, a low copper content in ores has been observed (ores containing 02–03% copper are used for processing in Canada and the United States, and ores containing at least 04% copper are used in Russia []) owing to the exhaustion of rich copper resourcesThe flowsheet of processing copper ores is developed for each

Ore Dressing Methods 911 Metallurgist

WebApr 10, 2017 Oredressing methods fall naturally into two general subdivisions— (1) concentration methods and (2) directrecovery methods (amalgamation and leaching or wet methods) Concentration methods are employed to remove worthless gangue material and concentrate the valuable minerals of the crude ore in a smaller bulk

(PDF) Overview of Mineral Processing Methods

WebAug 3, 2015 It is a process of ore preparation, milling, and ore dressing or ore beneficiation It was founded that enhancement of the concentration of Mn is more than 5% with the shaking speed condition

Mineral deposit Formation, Geology, Ore Britannica

WebMineral deposit Formation, Geology, Ore: Mineral deposits form because some medium serves as a concentrating and transporting agent for the ore minerals, and some process subsequently causes the transporting agent to precipitate, or deposit, the minerals Examples of concentrating and transporting agents are groundwater, seawater, and

An Introduction to the Chemistry of Metal Extraction

WebJun 30, 2023 Concentrating the ore This simply means getting rid of as much of the unwanted rocky material as possible before the ore is converted into the metal In some cases this is done chemically For example, pure aluminum oxide is obtained from bauxite by a process involving a reaction with sodium hydroxide solution

Colour performance investigation of a Cr2 ScienceDirect

WebApr 1, 2014 A novel process for preparing Cr 2 O 3 from chromite ore has recently been developed in our laboratory First, chromite ore was decomposed by a high concentration of a KOH aqueous solution under an oxidative atmosphere to obtain potassium chromate (K 2 CrO 4) [18], [19], [20]

Ores and Minerals Introduction, Extraction, Concentration

WebOct 18, 2023 The ore is generally associated with Earthy impurities like Sand, rocks, and limestone Known as Gangue or Matrix A substance added to ore to remove the impurities is called flux The combination of gangue with flux in ores forms a fusible material called Slag The concentration of ore is the process of eliminating gangue from the ore

(PDF) Techniques for solubility enhancement of poorly

WebDec 20, 2012 The pH changes, salt creation, complexing agents, particle size reduction, cosolvency, etc are just a few of the approaches used to enhance the solubility of poorly soluble pharmaceutical drugs

Gold processing Mining, Concentrating, Refining Britannica

WebGold processing Mining, Concentrating, Refining: The nature of the ore deposit determines the mining and mineral processing techniques applied Oxide ore deposits are frequently of such low grade (eg, 3 to 10 parts per million) that extensive mineral processing cannot economically be justified In this case they are merely shattered by explosives and then